To qualify the procedure, three consecutively thriving simulations needs to be carried out. Procedure simulation should generally final no lower than the duration of the actual manufacturing procedure.

Evaluate and explore the historic sterility constructive benefits from the exact same solution or filling line For the reason that previous productive media simulation.

Jobs performed in the buffer location must be restricted to These for which a controlled natural environment is important. Just the household furniture, equipment, materials, as well as other products expected with the tasks to be done may very well be introduced into this area, and they must be nonpermeable, nonshedding, and immune to disinfectants.

The method simulation test makes it possible for a wonderful simulation of the common aseptic manufacturing process like all methods and worst instances, according to GMP regulation [four].

or colder. Samples of Low-Risk Compounding— Single transfers of sterile dosage types from ampuls, bottles, baggage, and vials making use of sterile syringes with sterile needles, other administration equipment, and various sterile containers. The contents of ampuls require sterile filtration to remove any glass particles. Manually measuring and mixing not more than three created items to compound drug admixtures and nutritional methods. Excellent Assurance— High-quality assurance tactics involve, but are usually not limited to, the subsequent: Regime disinfection and air excellent testing in the direct compounding surroundings to reduce microbial surface contamination and manage ISO Course 5 air high quality (see Table 1). Visible affirmation that compounding staff are adequately donning and carrying correct goods and kinds of protective garments and goggles. Evaluate of all orders and offers of substances to guarantee the right identity and amounts of components had been compounded. Visible inspection of CSPs to ensure the absence of particulate make any difference in remedies, the absence of leakage from vials and bags, and also the accuracy and thoroughness of labeling.

Right after good introduction into the DCCA of supply things necessary for and restricted to the assigned functions, they are so organized that a clear, uninterrupted path of HEPA-filtered air will bathe all vital web sites continually over the prepared methods.

Business media-fill kits generally will not mimic the particular techniques executed in a pharmacy and for that reason it is strongly recommend that sterile media be purchased in bags, ampules and vials (along with nonsterile media as powder for prime chance compounders) and substituted for the actual factors Employed in the most get more info advanced and challenging strategies. For illustration, If the pharmacy employs nonsterile bulk API to generate an aliquot bag off of which you then draw affected individual-distinct CSPs, then Probably that would be a chance for any media-fill.

Although no guideline mentions that the samples for fertility testing shouldn't be taken just before incubation of media fill, it is usually recommended to accomplish the fertility test once the analysis in the media fill.

Biochemical and/ or genetic profile with the contaminating microorganisms shall even be as compared to that of microorganisms received from testing applications together with sterility tests, bio burden and environmental checking programs (air viable, devices surfaces, water methods and staff), so that you can assist detect the possible sources with the get more info contaminant.

Inspectors shall be properly trained to assure that models are preserved in their primary tray. There shall be no again-filling with models from other trays to guarantee the fill order continues to be traceable

). All CSPs which are intended to be options should be visually examined to the presence of particulate make a difference and never administered or dispensed when these make a difference is observed. The prescription orders, published compounding technique, planning information, and expended components used to make CSPs in all contamination threat ranges are inspected for accuracy of appropriate identities and quantities of ingredients, aseptic mixing and sterilization, packaging, labeling, and envisioned physical appearance just before They can be administered or dispensed.

The welder has just one consumable — one-use cutting blades. To be certain thoroughly clean and sterile welds, slicing blades are discarded following use.

Precision The intermediate precision from the ACD may be decided on The idea of your day-to-day variants in overall performance on the accuracy steps. As a result, the pharmacist have to hold a each day file of the above-described precision assessments and critique the results as time passes.

The tank containing the filtered Remedy is then linked sterile silicon pipeline and filling performed in ampule without utilizing using on-line cartridge filters/filter housing about the equipment.

Romeo Miller Then & Now!

Romeo Miller Then & Now! Michael Jordan Then & Now!

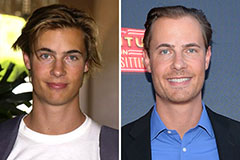

Michael Jordan Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!